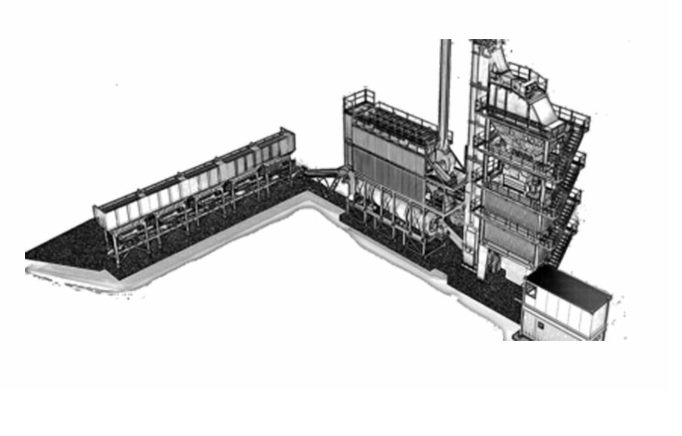

Asfalt Toplu Karıştırma Tesisi :

TURKÇE :

Asfalt plentleri; çeşitli kapasitedeki modelleri, kalitesi ve ekonomik işletme maliyetleri gibi özellikleriyle müşterilerimizin isteklerini karşılayabilmektedir.

Genel Özellikleri :

- Kolay ve hızlı montaj, işletmeye alma ve demontaj için dizayn edilmiştir.

- Tüm elektrik bağlantıları, hızlı montaj amacı ile sadeleştirilmiş bir şekilde dizayn edilmiştir.

- Geri kazanılan filler için filtre altında bulunan filler bunkeri

- Zahmetsizce filtre değiştirilebilme özelliği

- İstenilen türde yakıtla çalışabilme seçeneği. (diesel, doğal gaz, fuel oil)

- Kompakt tasarımı sayesinde kolayca montaj ve demontaj yapılabilme özelliği

- NiHard dökümleriyle uzun ömürlü mikser

- Yüksek performans ve düşük fiyat

- Asphalt Plant

ENGLISH :

Asphalt Batch Mixing Plant :

We can produce mobile or fixed asphalt plants with capacities of 60-240 tons / hour. High quality asphalt plant are produced with experienced staff.

Batch Mix Asphalt Plants Advantages

Optimum price, high performance

Precision weighing and high quality blend

High efficiency rotary dryer and burner

Easy Maintenance

7/24 after sale support

Possibility of asphalt mixing plant spare parts at reasonable prices

Operator friendly asphalt plant automation system

Easy assembly and disassembly possibility

Products suitable for different asphalt production (mastic asphalt, colored asphalt, recycling)

Cold Feed Bins

Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader.

Cold feed bins are used to dosage the different aggregates used in the mix to the drying drum.

Our Advantages;

- Thanks to its functional design, it facilitates transportation and installation. Attachments have bolted design.

- Thanks to its high strength silo casing and twisted body undergoes no change in shape under load.

- Thanks to the frequency-controlled dosing bands, each material can be supplied in any desired rate.

- The flame size of the dryer burner can be controlled automatically with the measurement sensor (optional)

Asphalt Plant Dryer

Dryer creates a maximum heat transfer surface thanks to its special wing design. With minimum fuel consumption, it allows the removal of humidity of aggregate and heat it up to the desired temperature.

Our Advantages;

- Dryer rollers and rings are manufactured from long-life forged steel.

- Easily interchangeable bolt-type compensation springs that distributes body load evenly

- Suitable for stainless steel insulation coating and heat transfer, rockwool covered body

- With soft starter support, operation without problem under load

- Automatically adjustable burner according to humidity and amount of aggregate (optional)

Aggregate Screen

The Asphalt plant screen the aggregate in a perfect precision thanks to its low slope and special screen mesh formation.

Features;

- Screen surface area varies according to asphalt plant capacity

- Dust-proof design

- Front maintenance cover opening through pneumatic system

- Easy changeable screen mesh

- 4-5-6 types of screen fractions

Batch Mixer

Asphalt plant mixer provides long wear parts life and homogeneous blend.

Features;

- Heavy duty group high quality reducer.

- Heat and abrasion resistant inner liners

- Long life arms and shoes

- Double-valved discharge system

- Discharge valve with external resistance heating

Bag Filter

Asphalt plant filter system separates the gas and dust generated during asphalt production. The decomposed filler dust can be used in mixture if desired.

Features;

- Input and output temperature measurement

- Clean air valve to protect bags from burns

- Nomex filter bags with vertical casette

- Dust-proof design

- Easy bag changing

- Reverse air flow bag cleaning system

- Insulation suitable for climate conditions and heat transfer

Automation

Asphalt plant automation is simple and user friendly in terms of ensuring full control of the platform.

Features;

- Full automatic control possibility

- All electrical motors, valves, level switches, open and closed positions of the valves in the system and getting information about fault conditions

- First class material and equipment, IP 55 protection class panel

- Insulated, container, air-conditioned, operator cabin with large internal volume

- Full control on plant with wide field of view

- Ability to provide work safety with emergency stop system

Spare Part, Revision, Handling Service

We can meet the needs of transportation, revision, maintenance, spare parts of every brand and type of asphalt plant and can re-produce the equipment.

Some spare parts;

- Elevator chain and elevator bucket

- Filter bags

- Drier ring and drums

- Mixer shoe and arms

- Valves – Pistons – Switches

- Asphalt and hot oil valves

- Asphalt and hot oil pumps

- Springs and valves

- Heater cables

Değerlendirmeler

Henüz değerlendirme yapılmadı.